UNATIONAL Road and Way Group

Road Construction

01

topography

Topography is the study of the forms and features of land surfaces. The topography of an area may refer to the land forms and features themselves, or a description or depiction in maps.

02

Preparation of executive plans

Preparation of drawing maps of the area and technical programing

03

Excavating & road grading

Before a drop of concrete is poured, you need to build a foundation. Without it, the road will lack durability, especially as the surface material begins to show signs of wear. Excavating and grading involve preparing the land by moving soil to flatten, build up and slope the road location. Excavating is important for removing large materials and obstacles from the site like boulders, trees, stumps and other types of debris. Excavators are also used to dig holes, pile dirt around the site and slope the land to meet the needs of the road. Last but not least, excavators dig trenches for irrigation, creating a pathway to direct water away from the road surface.

04

Planning

This multi-faceted step involves everything from site evaluation (including review of the current soil/material on site) to project design. Planning also includes scheduling and logistics such as securing the proper equipment, labor and any subcontractors.

05

Earthworks equipment

This phase begins with site preparation to clear dirt, trees and other vegetation. Some of what is removed may remain onsite to be used for erosion control or backfill. Before grading begins, the subgrade is prepared by adding or removing rock and dirt as necessary. This is known as "cut and fill." Next will be the grading of the land and compacting to make sure the road has a stable foundation. Earthworks equipment needs may include: Motor graders- Excavators- Crawler loaders- Crawler dozers- Scrapers- Dump trucks- Backhoes Skid steers

06

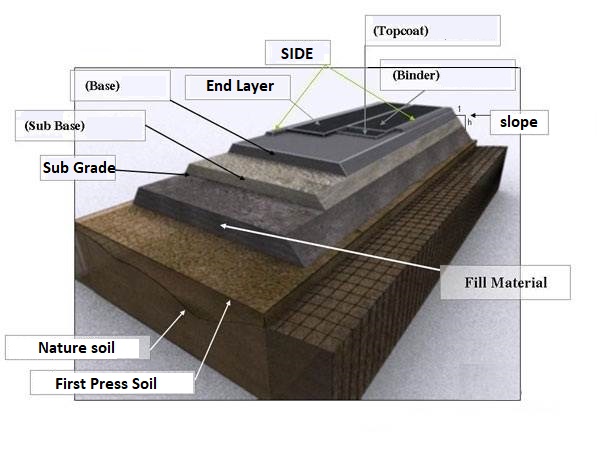

Aggregate

Crews will add a layer to the subgrade, usually called the aggregate or rock layer. A motor grader or crawler is often used to create a crown in the road surface for proper drainage. After grading is complete, the aggregate is compacted to solidify the base. Aggregate equipment needs may include: Motor graders- Crawler loaders- Dump trucks- Dozer.

07

Paving

For asphalt roads, trucks will bring in the hot asphalt mix. A paver pushes the truck at a slow speed to distribute the asphalt at the proper depth. A roller follows the paver to create optimal compaction. For concrete roads, the process is more time consuming and labor intensive. A placer machine allows a concrete truck or dump truck to unload directly onto a conveyor belt. The belt places the concrete aggregate material and begins to spread it. Then a slipform mover moves along to smooth the concrete. Next a tinning machine makes grooves in the concrete to improve surface traction and drainage. After the concrete has dried, saw cuts or expansion joints are made to allow the concrete to expand and contract with temperature changes.

08

Asphalt

A flexible asphalt paving project will generally involve these layers: Subgrade - Usually a mixture of gravel and sand or dry lean concrete (DLC). It's often called the frost protection layer for its ability to minimize the effects of freezing and thawing. Base - The middle layer, also known as the binder. It consists of large aggregate mixed with oil to add strength to the surface. Surface asphalt - The top layer is made up of small aggregate, sand and oil-based bitumen which hold everything together. This mixture also creates the qualities that make asphalt roads dark black, smooth and shiny.

09

Support

A rigid paving project is similar, with the addition of the following additional layers: Anti-friction membrane - Placed on top of the base, it's usually made of polythene sheeting. Insitu concrete slab - Prepared on site, this layer goes on top of the membrane to add extra strength. The final layer (usually asphalt) goes on top of the slab.

10

line drawing

Drawing and design with Standard Colors

11

Traffic signs

A Z

12

Road Lighting

z a

road construction Machines

Articulated Dump Truck

Powerful, efficient, and capable of working across all types of surfaces. Great for heavy hauling of road construction dirt and debris. 4 available models (49,591 - 69,886 lbs).

Backhoes

Our backhoes offer superb, multifunction performance. Great for digging trenches, loading trucks, busting up blacktop, placing pipe or moving materials. 4 available sizes (13,822 - 25,588 lbs)

Compact Track Loaders

Vertical-lift design rises high and reaches far for quick and easy loading. Attachments add versatility for site prep and moving rock and dirt. 4 available sizes (8,423 - 12,100 lbs).

Crawler Loaders

Provide muscle and versatility for the most demanding jobs. Great for excavating, loading trucks, backfilling or grading. 2 available sizes (40,614 & 45,178 lbs).

Dozers

Wide variety of applications including site development, clearing, roadbuilding and more. Advanced hydraulic features, fuel-saving technology, easy operation. 8 available models (17,510 - 96,100 lbs).

Excavators

Rugged and dependable, they're the workhorses of your fleet. Great for trenching, site prep, loading or placing pipe. Available in compact, mid-side and large (3,800 - 188,750 lbs)

Graders

In-cylinder position sensing allows the machine to stay on grade. Fully integrated and factory calibrated. 8 available models (40,400 - 47,620 lbs)

Scraper Systems

Great for pulling ejector and carry-all scrapers, disks, and rollers. Rubber-tire and track options make it easy to move dirt on any surface. 11 available models (517 - 691 hp).

Skid Steers

Power, performance and maneuverability for trenching, site prep and moving rock. More than 100 attachment options including buckets, augers and hydraulic hammers. 6 different models (6,140 - 10,000 lbs).

Tractor Loaders

Designed for grading, built for variety of tasks. Works with a multipurpose bucket, box blade, or power takeoff. 2 available sizes (10,569 - 11,326 lbs).

Wheel Loaders

More reach, comfort and control. Attachments offer unparalleled versatility. 20 different models (compact, mid-size, large).

Roller

A roller is a piece of heavy equipment specifically designed for soil compaction applications. Several types of rollers are available, and each compacts the soil in different ways.

we are MotivAQ

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed auctor turpis eu arcu sagittis, id sagittis justo eli suscipit. Aliquam erat volutpat. Integer finibus sem felis Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed auctor turpis eu arcu sagittis

Our method has been tested